🎃Happy Halloween Sale🎃Get 12% Off For All Order

Menu

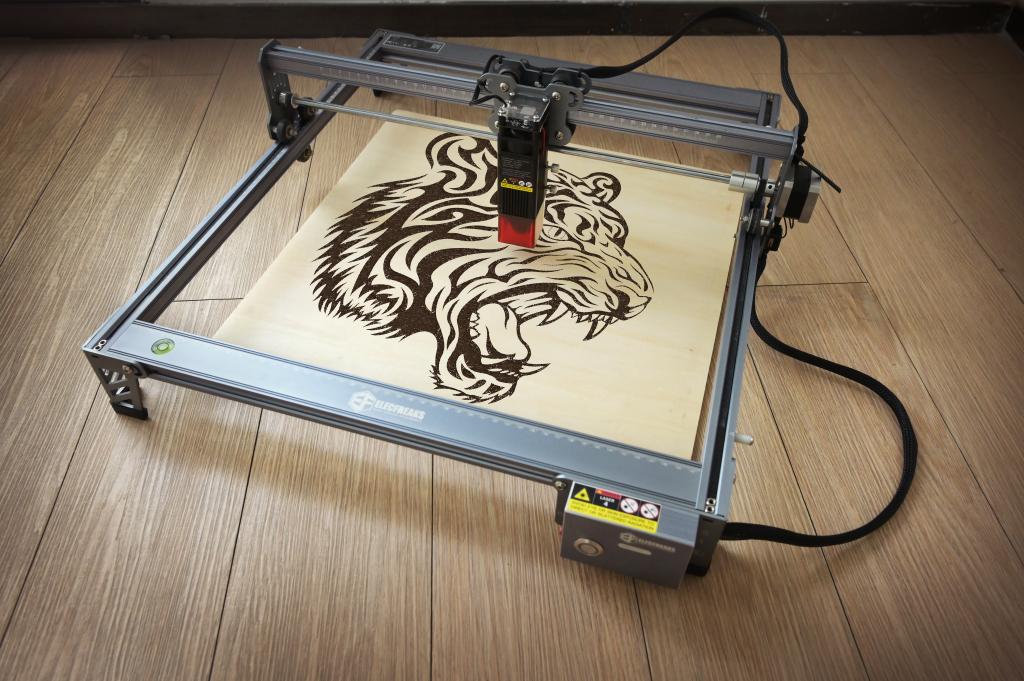

The laser engraving machine we are familiar with will only appear in some large factories or workshops, and people cannot use it in their underground warehouses or homes. When the global epidemic is severe, people have no way to go out for activities and can only spend time at home. Therefore, all kinds of exquisite small gifts, or furniture, accessories, etc., have been made.

So naturally, the tools to make these things are also selling well. Therefore, a low-power version of the laser engraver suitable for home use was born.

CO2 laser engraver: It uses jets of carbon dioxide to penetrate the material. However, it has low efficiency; It is, therefore, ideal for engraving and cutting non-metallic materials such as paper, fabric, leather, and wood.

Diode laser engraver: It is becoming very popular with hobbyists and manufacturers. The diode in this laser is usually an optoelectronic device that converts electrical energy into light, resulting in high-intensity coherent light used to engrave objects.

Fiber Laser Engraver: Creates powerful laser beams by pumping extremely intense light down fiber optic cables. Note that these cables are generally doped with ytterbium to release high-capacity energy in the form of photons.

A laser engraver works by creating a focused laser beam and then directing it onto a material. When done correctly, the laser leaves a permanent mark on the material that is highly resistant to abrasion. How the laser is generated and channeled depends on the technology of the laser in question, but it is passed through a lens to focus it.

What happens when the laser hits the material depends on the user’s objective. The laser generates an enormous amount of heat at a certain point on the material, causing the material to vaporize or simply burn enough to create a visible contrast.

Greater material compatibility makes it easier to use the laser engraving machine for different applications. You can get more creative with your projects and explore different materials.

The best laser engravers are compatible with a variety of materials like wood, leather, paper, cardboard, glass, etc. The more powerful your laser engraver, the more materials you can generally engrave and cut. It is therefore important to check the hardware compatibility of a laser engraver before purchasing.

The common materials used for laser engraving include:

1. Glass: This is one of the best materials for laser engraving. Laser work can be done on all glasses to achieve aesthetic effects. It can be wine glasses, bottles, vases, and cups.

2. Wood: This is a popular engraving material because it is cheap and readily available. Moreover, you can use any type of wood for laser engraving and cutting to achieve different results. The most common types of wood used for engraving are plywood, MDF, solid/solid wood, natural wood, chipboard, HDF, and veneer.

3. Marble and Granite: These materials are mainly used for engraving photos because marble and granite are very good at giving great contrast to the engraving. Use dark materials for better aesthetics.

4. Bricks and stones: These are ideal for engraving objects that will be exposed to various weather conditions. This makes them ideal for engraving pieces used on monuments and outdoor patios.

5. Leather: Like fabric, this material can be personalized with an engraving. Engraved leather is in high demand and the most commonly engraved materials are natural leather, suede, faux leather, suede, and Alcantara leather.

6. Metal: All types of metals can be engraved, but the most common are: stainless steel, iron, steel, brass, aluminum, and silver.

7. Acrylic: It is a durable, reliable, and lightweight alternative to glass.

Good software allows you to take full advantage of the hardware capabilities of your laser engraver. Both design and motion control software is important in the software suite for any laser engraver. Lightburn, LaserGRB, and Inkscape are some of the famous and feature-rich options available for your laser engravers.

It is a control and editing software package. Lightburn is used to import a variety of bitmap and vector graphic image formats. With this software, you can create new artwork, and edit and organize your vector graphics. It is very efficient to use with a laser engraver because you can simply send your file directly to the machine.

1. Works with a variety of popular image formats and vector graphics, including AI. DXF, SVG, GIF, PNG, PLT.

2. A native application is written for Linux, Windows, and Mac OS

3. Lets you create, organize, and edit new vector shapes in the editor.

4. Several powerful functions such as welding, node editing, offset, and Boolean operations

5. It has multiple passes, speed, power, dither mode, cut order, brightness, and contrast.

It is a free laser engraving software designed for DIY laser engravers. Rated as the most desirable Windows GCode Streamer, you can use this software to upload or stream your GCode path to burn images, images, and logos. Its unique properties are further enhanced as it is specially designed for amateur laser engravers and cutters.

1. Powered by custom buttons

2. Ideal for engraving images with vectorization, dithering, and conversion to grayscale.

3. GRBL configuration for import and export

4. Provides real-time projection and job preview

5. Offers different color scheme adjustments for use with different eyewear

6. Has a home button, resume button, power hold button, and GRBL reset button

It is free and open-source software that is generally considered to be the most effective Adobe Illustrator alternative. Its popularity is supported by the fact that it is constantly evolving and improving the user experience of using laser engravers.

1. Its native format is Scalable Vector Graphics (SVG)

2. It provides a means of royalty-free graphical formatting – markup language i.e. H You can use commands to create your unique designs

3. Works on all operating system platforms with equal ease, including Windows, Linux, and Mac OS

4. Has clones, pen tools, shape tools, and text tools for creating objects

5. Makes object manipulation easier by grouping objects, transforming, raising, and lowering operations, and layers, and aligning and distributing commands.

6. Fill and outline with pattern fills, path markers, color pickers, dashed strokes, and more.

7. Provides text support with text in a shape, multi-line text, text on a path, and letter spacing, among others

Laser cutters and laser engravers are virtually identical machines. The main difference is in the power of their laser and the materials they can work with.

Laser engravers have a weaker laser intended only for engraving. However, it is possible to modify the laser engraver to act as a laser cutter. Setting it too low speeds and high laser intensity will cut wood, paper, and some plastics.

Laser cutters, on the other hand, have a much more powerful laser that can both engrave and cut materials. Naturally, laser cutters cost more than engravers. Their CO2 lasers and fiber lasers are higher in price and also require higher technical skills to operate.

If your main purpose is to personalize die-cut items or engrave keychains, bookmarks, and simple models, a laser engraver is for you. A laser cutter is an ideal choice when custom designs need to be cut and a full range of laser cutting and engraving capabilities are required.

Most laser machines you can buy online can engrave, but not all laser engravers can cut.

Low-power diode lasers are preferred for engraving soft materials such as cardboard, paper, and fabric. Higher power diodes are now also becoming more common, and we have seen manufacturers pack multiple diode lasers into one tool head to provide higher output intensity than previous diode laser engravers. These new tool heads can provide similar output intensities to CO2 lasers but are very expensive and not available in large quantities.

There are many low-power diode lasers and more affordable open-frame devices available, generally ranging from $200 to $500. Best suited for soft materials, paper, fabric, etc. The effect is not as good as that of a CO2 laser cutter, but at least the CO2 laser cutter is significantly more expensive than these diode laser engravers.

Ultimately, the efficiency and ease of use of laser engraving are very much dependent on the software. LightBurn is often considered one of the best software out there. Many brands on the market have developed their own laser engraving software, but most of them are in beta version. For very complex images, engraving and cutting may not work smoothly, in contrast, there are more laser engravers that are fully compatible with LightBurn.

To make your selection easier, I’ve tested many brands of laser engravers to narrow down the various options. Whether you want an affordable laser engraver or are looking for a machine that meets your specific requirements for materials or applications. Personally, I think the TOOCA L1 laser engraver can meet all your needs.

TOOCA L1 Laser Engraver is one of the most cost-effective laser engraving products on the market. It has very simple assembly steps and you can build it up by yourself.

It is easy to carry with the lightweight and you can work on it anywhere and anytime.

TOOCA L1 laser engraver compared to other brands of laser engraving machines. The whole body is made of anodized aluminum alloy, and the L-shaped silicone feet and 8mm steel rails ensure the precise and smooth movement of the laser head when working.

The safety shield on the laser head complies with FDA Class 1 safety level and can filter 90% of ultraviolet rays, allowing users to work with the machine without wearing goggles. The fan with a carbon filter effectively absorbs smoke and dust, protects the user’s respiratory system, ensures the quality of the engraved product, and prevents the surface of the work from turning black.

This laser engraver supports Windows/Mac OS computers and TF cards, providing users with multiple options. It supports common file formats including SVG, DXF, JPG, JPEG, PNG, and BMP. It also works with many software applications, such as the most popular LightBurn, LaserGRBL, etc. on the market.

The brand also provides a very powerful WIKI Library, which contains a variety of interesting cases provided by the brand, and you can enter the WIKI Library to download patterns at any time. They hire professional designers to regularly enrich the database, and users are very welcome to upload and share their projects with the community.

First, check whether your material fits in the working area of the laser engraver and cut it if necessary. Also, be prepared to do test cutting or engraving and bring spare equipment.

You don’t necessarily need additional tools when working with a laser engraver, but in my experience, the following tools can come in handy:

1. Utility Knife: For cutting materials that have not been completely cut by the laser cutter, or for trimming paper and cards.

2. Painter’s Tape/Tape: For masking the surface of your material to prevent burn marks and for masking off lightweight materials.

3. Tape Measure/Calipers: Used to measure dimensions and ensure your final objects are the correct size.

The four most important parameters of a laser cutter are power, speed, frequency, and focusing distance.

1. Power: Specifies the output power of the laser. Generally adjustable from 0 to 100% (maximum power). High power is used for cutting thick materials, and lower power is used for engraving and cutting thin materials like paper.

2. Speed: Determines the speed at which the laser head moves. For engraving and cutting thin materials, the speed is usually set to (almost) maximum.

3. Frequency (Hz, PPI): The Frequency parameter specifies the number of laser pulses per second. The frequency depends entirely on the material used. For example, woodcuts are best at around 500-1000 Hz and acrylics are recommended at 5000-20000 Hz to get a smooth edge.

4. Focus: As mentioned before, there is a focus lens in the laser head. The focal point (where the laser beam is thinnest) should be at or slightly below the surface of the material for most applications. To ensure this, the material must be at a certain distance from the lens. The exact distance depends on the type of focus lens used.

Believe that by now, you have prepared the necessary tools. The operation process of each laser cutting machine is different. I am more familiar with TOOCA L1 Laser Engraver from ELECFREAKS. Then I will take TOOCA L1 as an example to talk about the basic operations.

The first step is to place the laser cutting machine on a large working platform, which can be the ground or a table. Place the material you want to engrave or cut in the work area. (Note: I personally recommend placing honeycomb panels under the material. This can prevent the laser beam from damaging the ground or the working platform during cutting or engraving.)

In the second step, after placing the material for engraving or cutting, use the focusing aid tool that comes with the laser cutting machine to focus.

The third step is to turn on the switch of the laser cutting machine and connect the laptop to the USB cable. (Note: Some laser cutting machines also support offline operation or SD card operation.)

The fourth step is to import the pattern you want to engrave or cut into the software you want to use. I generally use LaserGRBL, it is more convenient to use.

The fifth step is to set the moving speed and frequency of the laser head in LaserGRBL. (Note: Set your parameters according to the material you are carving or cutting)

Finally, click Get to work. After waiting for a while, you can get the case you want.

Using a laser engraver can be very dangerous and harmful to your health. Before using the laser engraving machine, you’d better do the following protective work:

Lasers can cause significant eye damage. For safety reasons, consider wearing laser safety goggles. When choosing such a protective tool, you should consider glasses that directly match the type of laser engraving you are going to use.

This should be easy as information about the laser can be found in the instruction manual. This includes information such as optimal density and wavelength range. Make sure you wear your laser glasses during the engraving process and only take them off when you are no longer using the device.

Laser cutters readily generate fumes, particulates, metal fumes, and fumes from substrates that can be highly toxic. It is important to wear personal protective equipment when using a laser cutter. Additionally, stores selling these tools must have well-equipped filtration systems, which is important to reduce the likelihood of health hazards from toxic fumes.

Fume extractors are ideal for such workplaces as they help extract dangerous fumes from the air and protect you from exposure to heavy metals and toxic particles.

This is usually caused by zinc fumes released when cutting certain alloy steels. Common symptoms of zinc fumes include pain, coughing fits, flu, and fever.

Chemical exposure may irritate eyes, skin, mouth, and noise.

Over time, toxic fumes build up in the body causing unwanted chemical reactions. This could eventually lead to lead poisoning and kidney problems.

Exposure to carcinogenic compounds is common, especially in the presence of hexavalent chromium. It is a dangerous particle that can cause cancer. Also, numerous research studies indicate that this unpleasant particle can immediately cause several side effects such as B. Skin wounds, nose, mouth, and eye irritation.

Laser machines, especially those using CO2, typically emit hazardous fumes, which is why these devices need to be ventilated. You should therefore consider working in a well-ventilated room. While modern laser engraving systems come with exhaust systems that keep the inside of the laser cutter and the air around the laser safe, be sure to open doors and windows for free airflow.

Laser engraving operations can be risky because laser beams are hot and powerful when engraving and cutting. Therefore, accidental contact can be dangerous. In addition, laser radiation can damage the eyes. Fumes rising from the surface of the burnt material can also be dangerous.

As such, most engravers have various safety features such as a laser beam enclosure to prevent contact – and a cover to protect your eyes from harsh UV rays. It’s a good idea to buy safety glasses and gloves to protect yourself. Also wear a mask when using a laser engraver.

A laser engraver has replaced most traditional methods of engraving various materials. Because it requires no manual work and offers incomparable precision. A laser engraver is great for hobbyists, advanced artists, and professional players.

Laser engravers can create personalized gifts like purses and rings. You can use them to add a touch of beauty and uniqueness to signs and centerpieces. It can also add logos to keychains and tags.

Most laser engravers on the market have a lifespan of around 30,000 hours, but you can still find good units with over 35,000 hours or over 15 years with proper use.

Birch, balsa, and alder are all good woods for laser engraving, especially for beginners. They are high-density so are easy to cut and don’t generate much heat when engraved. They are also light in color which contrasts nicely with the darker woods.

Thicker woods are more difficult to laser engrave as they require more time and energy to cut. The finish of the wood can also affect the quality of the engraving. Wood that has been stained or varnished is more difficult to laser engrave than natural materials.

I recommend using Basswood Plywood, which can be easily found on the market, it is very suitable for beginners who are new to laser engraving, and the price is not expensive. You can buy it at ELECFREAKS.

The laser power needed to engrave wood depends on a number of factors, including the depth and speed requirements of the engraving job being done. Generally, a low-power laser is sufficient for most types of engraving, but more powerful lasers can be used for cuts.

It is also important to consider the type of wood to be engraved. Hardwoods like oak or maple require more strength than softwoods like pine or cedar. Before purchasing a laser, it is therefore important to determine the specific requirements of the project in question.

You will be dazzled by the variety of laser engraving opportunities on the market! Before you buy, be sure to think about what you’ll be using it for. But finding the best laser engraver is easy if you know exactly what you’re looking for and how you want to use the equipment for your craft.

Every engraving enthusiast wants a laser engraver—but for different reasons. Requirements vary in terms of material, design type, project purpose, etc. We hope our guide and advice helped you make the right choice for your first laser cutter!

Stay up-to-date with our latest promotions,discounts,sales,and special offers.